Bulk bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are industrial containers made of flexible fabric that are used for the storage and transportation of dry and flowable goods. FIBCs are usually made of thick polyethene and, depending on what is being held, range in size from 39 to 79 inches in height and 45 to 48 inches in diameter. Depending on the design, they are designed to hold 4000 pounds of materials. In this blog, we have discussed four different types of FIBC bags and how you can utilize them efficiently.

Different Types of FIBC Bags

Type A FIBC Bags:

These FIBC bags don’t offer any static protection. Static electricity is produced as items rub against the internal surfaces of the polypropylene-woven bag as it is filled and emptied. These types of bags are used for the transportation of non-hazardous products. Type A bags should not be utilised to store or transport combustible items or used in flammable or explosive conditions since they do not offer static protection.

Uses of Type A FIBC Bags

- Agriculture: Ideal for storing and transporting grains, seeds, animal feed, and other dry materials.

- Food Industry: Used for dry ingredients like sugar, flour, and salt, but hygiene standards must be met for edible items.

- Construction: Suitable for dry, non-combustible materials like sand, gravel, and cement; durable for rough handling.

- Chemicals & Minerals: Used in chemical and mining industries for non-hazardous, non-flammable materials like limestone and plastic pellets.

- Recycling & Waste: Efficient for collecting and transporting dry recyclables, such as plastic, paper, and metal scraps.

- Textiles & Fibers: Useful for transporting raw materials like cotton and wool, protecting fibers during transit.

- Pharmaceutical & Cosmetic: Stores non-hazardous, dry materials like powders; cleanliness is essential.

- Cleaning Products: Transports bulk dry cleaning agents like detergents for household and industrial use.

Type B FIBC Bags

It has no static electricity dissipation system. Type B bulk bags are made of materials with a low breakdown voltage (PBD) to avoid the occurrence of extremely energetic and hazardous propagating brush discharges. These FIBC bags are capable of preventing PBD, but they cannot be categorised as antistatic FIBCs because they do not remove the electrostatic charge. The typical brush discharges that can ignite flammable solvent vapours still happen.

Key Uses of Type B FIBC Bags

- Chemical Industry: Used for non-flammable powders like fertilizers and polymers, minimizing ignition risks in dusty settings.

- Food Industry: Suitable for dry ingredients such as flour and sugar, ensuring safe bulk transport with dust control.

- Pharmaceutical Industry: Handles non-flammable powders safely in environments with moderate dust explosion risks.

- Agricultural Products: Used for grains, seeds, and animal feed, reducing dust explosion risks during transport and storage.

- Mineral and Mining: Ideal for non-flammable minerals like limestone and clay, preventing static discharge in dusty environments.

- Construction Materials: Used for transporting dry, non-combustible materials like cement, reducing fire hazards.

- Recycling and Waste Management: Safely collects and transports fine dry materials, reducing explosion risks in dusty areas.

Type C FIBC Bags

These FIBC Bags are also referred to as groundable or conductive FIBC. They were initially made entirely of conductive materials. The most common material used to create groundable Type C FIBCs is non-conductive polypropylene interwoven with conducting yarns, typically in a grid pattern. The safe use of Type C FIBC depends on the connecting of conductive threads and the connection to the ground or earth. Human mistakes are possible while connecting and grounding these bags, just like it is with any manual process.

Key Uses of Type C FIBC Bags

- Chemical Industry: Used for flammable chemicals and powders, grounded Type C bags reduce static discharge risks.

- Pharmaceutical Industry: Essential for transporting combustible pharmaceutical powders safely in static-sensitive environments.

- Agricultural Products: Safely handles combustible grains, seeds, and fertilizers by reducing ignition risks.

- Food Industry: Suitable for transporting dry ingredients prone to static, like starch, in dust-prone areas.

- Mining and Mineral Industry: Ideal for flammable mineral powders, such as coal dust, reducing static buildup.

- Construction Materials: Transports combustible materials, like aluminum powder, safely with grounding.

- Paints and Pigments: Safely transports flammable powders, minimizing ignition risk.

Type D FIBC Bags

These FIBC Bags are anti-static bulk bags manufactured from static protective fabric to safely prevent the occurrence of incendiary sparks, brush discharges, and propagating brush discharges. The risk of grounding failure that is always present when conductive Type C FIBCs (grounded FIBCs) are used is eliminated by using CROHMIQ fabric to make anti-static bulk bags.

Key Uses of Type D FIBC Bags

- Flammable Materials: Type D FIBC bags are specifically designed for transporting and storing flammable materials, as they have built-in anti-static properties that help dissipate static electricity, reducing the risk of sparks or fire hazards.

- Chemical Industry: Ideal for transporting hazardous chemicals, including powders, granules, and non-flammable chemicals, where safety and prevention of static discharge are critical.

- Pharmaceuticals: Used in the pharmaceutical industry for storing and transporting sensitive dry materials such as active pharmaceutical ingredients (APIs), powders, and granules, ensuring a safe environment by preventing static buildup.

- Food Industry: While more commonly used in the chemical and pharmaceutical industries, Type D FIBCs can also be used for storing dry, non-edible food ingredients, where static control is required.

- Plastic and Polymer Manufacturing: Type D bags are widely used in industries dealing with plastic pellets and polymers, where static discharge could cause production issues or product contamination.

- Textile and Fibers: For safe transport of synthetic fibers and textiles, which can generate static electricity during handling.

- Powder and Granule Products: Used for transporting powders and granules that are susceptible to static accumulation, such as in the manufacturing of fertilizers, cement, and other dry, granular materials.

Types of FIBC Bags Based on Design

Mittal Technopack has grown to be a trusted name globally, driven by an unyielding passion for packaging excellence. Here, we’ll explore the different types of FIBC bags based on design, highlighting their unique applications and benefits.

1. U-Panel Bags

U-Panel bags are constructed from two pieces of fabric, forming a U-shape that provides extra durability. These bags are versatile, offering both strength and stability, making them ideal for carrying heavy materials in industries like agriculture and construction. Known for their durability, U-Panel bags maintain structure even under stress.

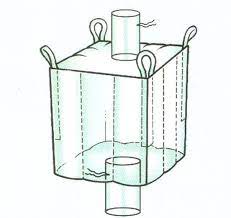

2. Circular (Tubular) Bags

Circular or tubular bags are created from a continuous piece of fabric, resulting in a seamless structure that minimizes leakage. Ideal for fine powders and grain, this design provides excellent protection against spillage and ensures safe handling. The tubular shape makes it a favorite choice for materials sensitive to leakage.

3. Four-Panel Bags

Four-Panel bags are designed with four individual panels sewn together, creating a square shape that maintains rigidity when filled. This structure is particularly beneficial for products that require stable stacking, as the square shape fits efficiently on pallets. Industries that transport heavy, stackable goods, such as minerals and chemicals, often rely on Four-Panel bags.

4. Baffle Bags

Baffle bags are equipped with inner baffles (panels) on all four sides to help the bag retain a square shape. This space-saving design is ideal for bulk goods as it prevents bulging and allows for compact stacking. Baffle bags are widely used in logistics and transportation, maximizing storage efficiency.

5. Conical Bags

Conical bags feature a tapered or cone-shaped bottom that allows for smooth discharge of materials. They are especially useful for sticky or hard-to-release products such as certain chemicals or powdered materials. This unique design minimizes waste and ensures the complete release of materials, making it highly efficient.

6. Single Loop and Two Loop Bags

For simpler handling, single-loop and two-loop bags provide an efficient solution with easy lifting capabilities. One or more big bags can belifted at the same time with a hook or with similar devices, which presents a significant advantage compared to standard four-loop FIBC where usually a forklift is needed and only one big bag is handled simultaneously. Often used in agriculture and construction, these bags are designed for frequent movement and are ideal for medium-weight goods.

7. Vented Bags

Vented bags are built with breathable panels, ensuring ventilation for products that require air circulation, like fruits, vegetables, and other perishables. This design helps to reduce spoilage, making vented bags a popular choice in the agricultural sector.

8. FIBC Bags with Liners

FIBC bags with liners offer added protection against moisture, contamination, and leaks, making them ideal for sensitive materials. Industries dealing with fine powders, chemicals, or food products benefit from this design, as it provides an additional layer of safety and hygiene.

Why Choose Mittal Technopack for Your FIBC Bag Needs?

At Mittal Technopack, we believe in creating durable, reliable, and protective packaging solutions that align with industry standards and regulations. Accredited with BRCGS (AA+), ISO9001, ISO22000, HALAL, KOSHER, and FSSC22000, and recognized as an AEO status and 2-Star Export House by the Government of India, our commitment to quality is unmatched.

Our FIBC bags are crafted with precision, ensuring they meet the demands of global markets with the perfect blend of functionality, durability, and customization. Whether you need U-Panel bags, Circular bags, or specialized Vented bags, Mittal Technopack is your trusted partner for high-quality, custom-made FIBC solutions.

Conclusion:

In addition to these uses, FIBC bags are used in other industries. FIBC Bags are an alternative to consider if you’re searching for a reliable, durable, and strong packing solution for your business. If you are looking for affordable and quality FIBC bags, then Mittal Technopack is your one-stop solution. Contact us today!