Flexible Intermediate Bulk Containers (FIBCs), also known as jumbo bags, play a crucial role in various industries, including agriculture, chemicals, food, and construction. When selecting the right FIBC bag for your business, two of the most commonly encountered types are U-Panel and Circular FIBC bags. Both have unique designs, features, and advantages that cater to specific needs. This blog will break down the features of each type to help you make an informed choice.

What Are U-Panel FIBC Bags?

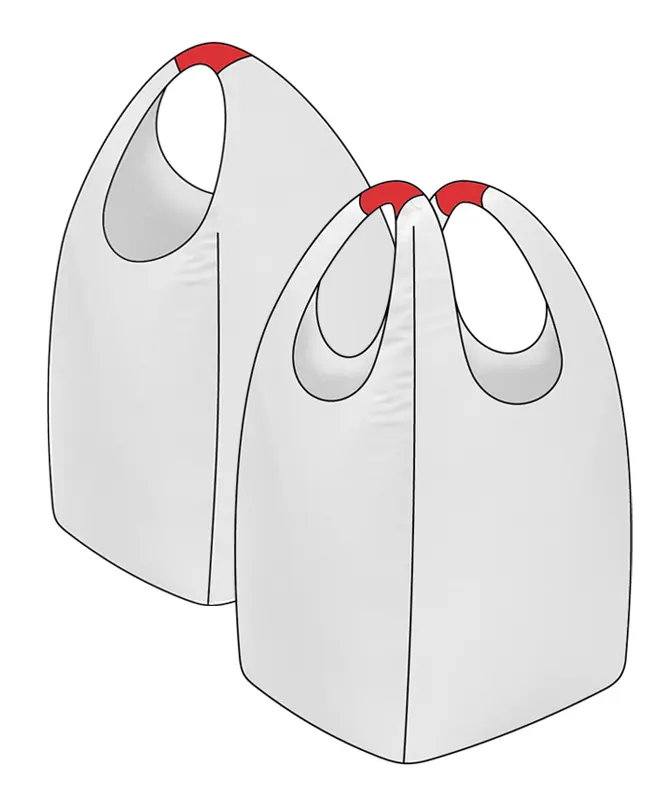

U-panel bags are constructed using one continuous piece of fabric that forms the bottom and two opposing sides of the bag, creating a “U” shape. The remaining sides and the top panel are sewn in to complete the structure. This design is widely recognized as a global industry standard and offers an excellent combination of strength, stackability, and affordability.

Key Features of U-Panel FIBC Bags:

- Stability and Space Efficiency: The U-panel design ensures a stable structure that is also space-efficient.

- Material: Made from durable woven polypropylene fabric.

- Customization: Available in various sizes and capacities, with optional features like liners and document pouches.

- Ease of Use: Equipped with spout or duffle tops for filling and flat or spout bottoms for easy discharge.

- Cost-Effectiveness: Affordable and eco-friendly.

- Lifting Options: Designed with lifting loops or straps for easy transport.

Advantages of U-Panel FIBC Bags:

- Suitable for stacking, making them ideal for storage or shipping.

- Highly durable, with a strong structure that ensures the safe transport of materials.

- Versatile in terms of capacity and custom options.

What Are Circular FIBC Bags?

Circular FIBC bags, as the name suggests, are made by weaving seamless polypropylene fabric into a cylindrical shape. The bottom is sewn to the cylinder, and a top panel or spout is added for filling. This unique construction eliminates side seams, making the bag more resistant to stress and wear.

Key Features of Circular FIBC Bags:

- Seamless Design: The tubular construction eliminates side seams for added strength.

- Material: Made from high-quality woven polypropylene fabric.

- Capacity: Available in various sizes and load capacities.

- Improved Durability: Designed for heavy usage and frequent transport.

- Customizable: Can include features like spouts, liners, and lifting loops.

Advantages of Circular FIBC Bags:

- No side seams mean better stress distribution and reduced risk of tearing.

- Ideal for powders and fine materials due to their reduced permeability.

- Excellent for bulk materials requiring extra durability during handling.

U-Panel vs. Circular FIBC Bags: Factors to Consider

1. Type of Material

- U-Panel bags are excellent for materials that require steady stacking during transport or storage.

- Circular bags are better suited for heavy materials and fine particles, as the seamless design provides superior containment.

2. Durability

- Circular bags have an edge when handling bulkier loads due to their cylindrical, seamless design.

- U-Panel bags offer great durability for standard shipping and storage requirements.

3. Cost

- U-Panel bags are generally more cost-effective, making them a popular choice for businesses looking to balance quality and affordability.

- Circular bags might have a higher initial cost but offer enhanced durability and reduced risk of wear and tear.

4. Customization

Both U-Panel and Circular bags are highly customizable. However, your choice of custom features (such as spouts, liners, and lifting options) should depend on your industry and specific material needs.

5. Applications

- U-Panel Bags: Ideal for industries like agriculture, food, and chemicals where stability and stackability are essential.

- Circular Bags: Best for applications requiring heavy-duty performance, such as construction or mining.

FAQs

1. Which bag is better for powdery or fine materials?

Circular FIBC bags are better for fine or powdery materials because their tubular, seamless design reduces permeability and leakage.

2. Can U-Panel bags handle heavy loads?

Yes, U-Panel bags are highly durable and can safely transport heavy loads, although Circular FIBC bags may provide better durability for exceptionally bulky or heavy materials.

3. Which type is more cost-effective for businesses?

U-Panel bags are generally more affordable and offer an excellent balance of strength, efficiency, and cost, making them a cost-effective option for most businesses.

4. What industries commonly use U-Panel FIBC bags?

Industries like agriculture, food production, and chemicals frequently rely on U-Panel bags for their ease of stacking and safe material handling.

5. Are both bag types customizable for specific needs?

Yes, both U-Panel and Circular FIBC bags can be customized with features like spouts, liners, document pouches, and lifting loops to suit specific requirements.

Which Should You Choose?

The choice between U-Panel and Circular FIBC bags ultimately depends on your business’s material handling needs. For standard loads and affordability, U-Panel bags provide a well-rounded solution. For heavy-duty applications or fine materials, Circular FIBC bags offer superior strength and reliability.

At Mittal Technopack Pvt. Ltd., we provide high-quality U-Panel and Circular FIBC bags tailored to your specific requirements. Whether you need stability, durability, or cost-effective solutions, we have you covered.